The solar energy industry has entered a high-growth phase, with global installed capacity reaching new milestones. In 2023, 447 GW of new solar capacity was added, marking an 87% increase year-on-year. Emerging markets in India, Africa, and Latin America are driving this growth alongside traditional leaders like China. Steel plays a critical role in supporting this expansion, forming the backbone of solar infrastructure and auxiliary systems.

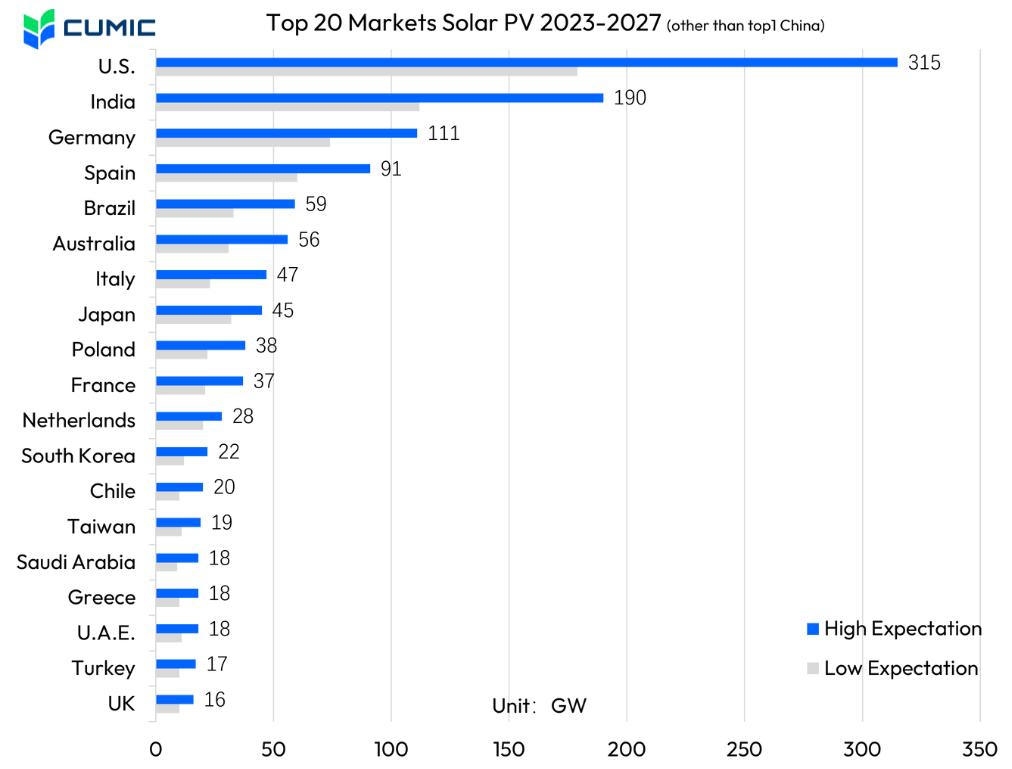

In addition to China, the United States and India are the largest solar markets, Germany and Spain are fast growth markets, and Saudi Arabia is expected to have the highest growth rate in the next five years. Emerging markets like Brazil, South Africa, the Middle East, and Southeast Asia are driving solar demand through supportive policies. India is advancing rapidly, with government initiatives expected to boost demand by 25% to 40% in 2025. Saudi Arabia and South Africa are investing in large-scale solar projects, while Brazil leads Latin America, doubling its capacity to 10.9 GW in 2022 with favorable policies.

Ground-Mounted Solar Systems

Centralized Systems: Ground-mounted solar PV racking systems typically employ galvanized steel and ZAM steel for components including posts, diagonal braces, inclined beams, cross beams, and connectors. Hollow sections are commonly used to fabricate these structural elements. Foundations for pile-supported posts often consist of galvanized helical piles or reinforced concrete piers.

Rooftop Systems: Industrial and residential installations use lightweight, high-strength steel to reduce load without sacrificing durability.

Floating Solar Systems

Support Structures: Utilize stainless steel, Zn-Al-Mg coated steel, and galvanized steel to ensure corrosion resistance and longevity.

Inverters: Enclosures are crafted from galvanized or color-coated steel to protect against environmental wear and tear.

Energy Storage Cabinets: Galvanized steel is used for storage systems that ensure grid stability and continuous power output.

Transformers and Substations: Transformers utilize silicon steel for cores, while galvanized steel is used for structural support. Substation foundations often incorporate reinforced concrete with steel reinforcements for durability.

Zn-Al-Mg Coatings

These coatings provide exceptional corrosion resistance, particularly for coastal and floating solar installations, where traditional materials may fail.

High-Strength, Lightweight Steel

New alloys reduce transportation and installation costs while maintaining structural integrity, making them ideal for remote or large-scale projects.

Focus on Sustainability

Decarbonization-leading mills are producing steel with significantly reduced emissions, supporting solar energy’s green credentials.

As a trusted leader in the steel industry, CUMIC understand the critical role materials play in the growth and success of solar energy projects. Our expertise and experience in providing tailored steel solutions brings solid foundation of durable, premier materials. For example, we delivered high-quality rectangular hollow sections to the iconic AES Andes Solar-IIB Project in Chile as well as high-quality steel to solar projects around the world. In addition to the specific steel type mentioned earlier, we are also capable of supplying a comprehensive range of steel products tailored to meet the unique demands of various industries.

Ready to power your solar projects with the highest-quality steel materials? Contact us today cumic@cumic.com and explore how our solutions can support the success of your solar energy installations, now and into the future. Wherever your projects are, we ensure that the steel you need is available and delivered on time, helping you stay ahead of project timelines and budget constraints.